The Basic Principles Of Double Pane Glass Panels

Table of ContentsThe Facts About Glazed Glass Panels RevealedInsulated Glazing Panels for BeginnersThe Facts About Double Pane Tempered Glass Panels RevealedThe smart Trick of Glazed Panel Window That Nobody is Talking AboutThe Best Strategy To Use For Double Pane Glass Panels For SaleLittle Known Questions About Glazed Wall Panels.

Periodically, there are problems associating with having way too much unrestrained daytime, in some cases referred to as glow. The obstacle is to aim for the greatest noticeable light passage (VT) and also the cheapest solar warm gain coefficient (SHGC) while not preventing the glass from being too reflective when watched from both the outside and also the interior, while controlling glare.The devices should be entirely set up in a factory as well as shipped to the site for setup on the building. The units are positioned on the floors, bundled in cages, making use of the tower crane as well as reduced right into place making use of a smaller sized crane or lift had by the glazing contractor. The mullion dimensions have a tendency to be somewhat bigger than a stick system as a result of their open section as compared to television shape of a typical stick curtain wall area.

Some Known Factual Statements About Double Pane Glass Panels

The interlocking upright mullions will commonly have 2 interlocking legs. One leg will certainly remain in the plane just behind the glazing pocket as well as the other at the interior face of the mullions. The interlocking leg in the aircraft of the glazing pocket will certainly be sealed by gaskets and is the primary line of defense versus water as well as air seepage - glazed glass panels.

Solutions whose attaching legs lock additionally jeopardize the ability of the system to suit motion. Some unitized styles are delicate to little abnormalities in the spacing of nearby modules; as an example, if the module joints are a little out of resistance, gaskets may not be properly compressed as well as moisture protection may endure.

Glazed Wall Panels - An Overview

These upstanding legs have gaskets that secure versus the walls of the lower straight. Some designs give one upstanding leg that gives one line of defense versus air and water seepage. More robust systems will supply two upstanding legs with gaskets on both legs. A splice plate or silicone flashing that is installed on top of both nearby systems as large panel double glazing they are put up on the building is typically needed.

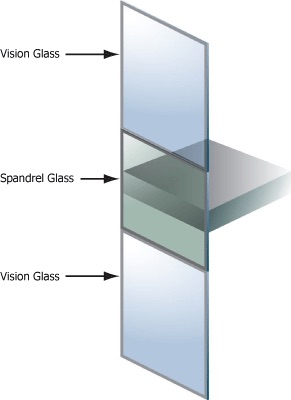

The pile joint is the horizontal joint where devices from adjoining floors meet. Positioning the stack joint at the sill of the vision glass (generally 30" above the floor) will lessen the dimension of the upright mullions. This positioning utilizes the back span of the mullion over the anchoring point at the piece to combat the deflection of the mullion below the piece.

The 3-Minute Rule for Fire Rated Glass Panels

Area screening of curtain walls: Need the field screening of curtain walls for air seepage and also water infiltration resistance, for high quality guarantee of drape wall fabrication as well as setup. Need multiple tests with the very first test on preliminary setups as well as later examinations at approximately 35%, 70% as well as at last completion to capture problems early as well as to verify ongoing workmanship quality. large glazing panels.

The details associated with this area of the BEDG on the WBDG were created by committee as well as are planned exclusively as a way to illustrate basic layout and also construction ideas only. Ideal usage as well as application of the concepts highlighted in these information will certainly vary based on performance factors to consider as well as environmental problems unique per project and, for that reason, do not represent the last viewpoint or referral of the author of each section or the committee members liable for the growth of the WBDG.

Constant steel sill blinking at the base of the drape wall secures the wall surface framework below from leakage with the drape navigate to these guys wall surface. Sill flashing need to have upturned end dams and fully sealed corners. Intermediate horizontal needs to be cried to the outside as well as prevent water from draining pipes onto the head of the glazing device below.

See This Report about Large Glazing Panels

Gasket height should represent the drape wall design pressure. Exterior cover splice sleeves are installed at the face of the pile joint during device area installation. Devices are designed as well as mounted with horizontal as well as vertical clearance voids to permit differential activity and also accommodate construction resistances. Stress equalized rainscreen gaskets form a primary weather seal at the face of the unitized upright pile joint in line with the straight rainscreen gasket at the system sill listed below.

Spandrel glass adapters are utilized to lower the depth of the glazing pocket to accommodate reduced profile of spandrel glass. Spandrel glass adapters must be completely bedded in sealer and integrated with polishing pocket edge seals to stop water leakage from glazing pocket to structure interior. System measurement of breeding head and sill squeezed out accounts enables specified floor to flooring deflection at the pile joint.

Intermediate horizontals stop at the face of the vertical unit jamb members at each end. Units are hung from the leading or face of the surrounding flooring or building framework using mated brackets and also area applied screws with a minimum of clearance for gain access to and also setting up. All links and brackets located within the systems protected or key weather condition seal areas are secured with ideal sealant materials during field installation.

Getting My Large Glazing Panels To Work

non-heat-treated) or completely solidified glass to remain in position till it can be replaced. glazed window panels. Whether heat-strengthened or completely tempered, heat-treated glass products are produced in a similar fashion and also using the same processing tools. The glass is heated up to around 650 C (1200 F), then force-cooled to create surface area as well as edge compression.

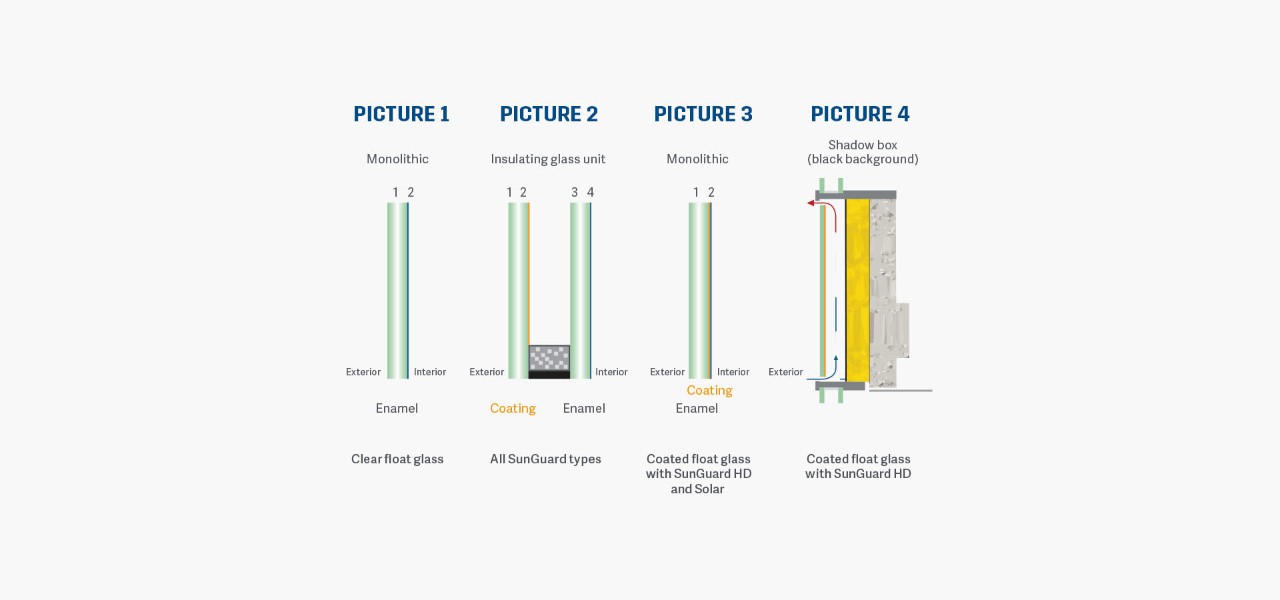

As shown in Number 1, insulation is usually utilized along with spandrel glass. When the insulation is to be used directly to the opacified surface area of the spandrel glass, it is essential to work with a glass spandrel fabricator, along with the sticky and also insulation distributors, to guarantee these items work with the opacifying product.